Pre-engineered steel warehouse construction costs are vital to be carefully considered before bringing a design into life. Take a look at a basic quotation for building a warehouse with pre-engineered steel in 2024.

Common types of warehouses in use today

Warehouses are designed and constructed for the main purpose of storage. Some warehouses are integrated with a factory or a small office. Costs are likely to vary depending on different methods of warehouse construction. There are recently 3 popular types of warehouses as follow:

- Conventional warehouses with an area of less than 1500m2 and a height of 7.5m. They are usually built of steel structure or iron frame, brickwalls, and roofing sheets from various materials (iron, steel, fiber cement, plastic).

- Pre-engineered steel warehouses with steel roofing sheets.

- Reinforced concrete warehouses.

By virtue of the benefits of saving costs and fast construction speed, pre-engineered steel warehouses have become very popular. So, how much does it cost to build a steel-frame warehouse? Let’s figure it out!

Construction costs of pre-engineered steel warehouses

The construction costs of a pre-engineered steel warehouse depend on a variety of factors such as details of structural design, location, environmental conditions, etc. Additionally, these costs vary depending on construction speed as well as types of materials required by the customers.

Quotation by main components

The quotation of building a standard pre-engineered steel warehouse includes 4 major sections as follow:

Concrete foundation costs

Foundation costs are recapitulated in a fee package including:

- Technology and materials used for the concrete foundation

- Labor costs

Standard steel framing system costs

A steel framing system includes main components such as frame truss structures, purlins and girts, bracing systems, etc. manufactured and fabricated in accurate measures and quantities according to technical drawings. The costs of pre-engineered steel framing system vary depending on the type of the steel frame truss structure, construction scale, environment factors (corrosion status, wind speed, geology, etc.) and the cost of raw materials in different periods of time.

Roofing costs

The preferred types of panels in warehouse construction are categorized based on the following factors:

- By placement and function: roof panels, wall panels, decorative panels, translucent / skylight panels, insulated panels, etc. The cost of each type of panels alters depending on the detailed needs of warehouses .

- By installing method: Through-fastened panels, seaming panels

- By technical design: Each construction requires appropriate sheeting profiles to meet the customer’s needs. At Pebsteel, the most-chosen profiles are PebWall®, LokSeam®, PebLiner™, PebRoof®, etc. which have specific functions, designs, and installing methods.

- By finishing treatment: Color-painted panels, galvanized panels (coated with anti-corrosive substances such as zinc, aluminum, magnesium).

Sub-structural steel framing system costs

A sub-structural framing system of a warehouse includes types of windows, doors, shutters, canopies, ridge ventilators, cranes, Mezzanine floor, fascia, walkways, staircases, etc. The system assists in developing the aesthetics and completing some pre-engineered buildings’ functions such as anti-flooding, natural ventilation, durability improvement and fully meeting customer needs of use.

Basic construction projects in the quotation of pre-engineered steel factories are presented in the following table:

| No | Construction projects | Basic construction materials of pre-engineered steel factories | Pebsteel products |

| 1 | Foundation structure | Reinforced concrete, layer of foundation, layer of paint | None. |

| 2 | Standard framing system | Including rafter system, bracing system, pole bracing, roof bracing, purlin bracing) and anchor bolt. | Clear span, Roof System, Single Slope, PebHybrid, Lean-To, Built-up Curved Rafter, Multi-Span, Multi-gable. |

| 3 | Roofing panel system | Types of roofing panels, types of wall panels, materials, surface treatment (color-coated or zinc-coated/ aluminum – zinc – magnesium alloy) | Types of panels : LokSeam, PebLiner, PebDek, PebSeam128, PebWall, PebRoofMaterials: AluPeb, GalvaPeb, Hyper180, PebLeed, Silver180, Alu-Zinc, PebInsul, PebFoamPanel colors: Aluminum, Blue Tooth, Green Tea, Opal Green, PEB Blue, White Cream |

| 4 | Sub-structural framing system | Canopy, walkway, ventilation system, overhead crane, etc. | Canopy, fascia, crane, ridge ventilator, checkered plate, ladder, grating, handrail, staircase, walkway, roof platform, Mezzanine floor, etc. |

| 5 | Accessories | Anchor bolt, accessories for aesthetic and building lifespan development. | Bolt & fastener, gable trim & corner trim, louver, gutter & downspout, etc. |

Fundamental element in building a sample pre-engineered steel factory and warehouse

Pebsteel participated in successfully designing and erecting the factory building combined with an office project in the Philippines in 2012 covering an area of 36,000 m2 and up to 3,700 tons in weight.

The building combining office and factory in the Philippines is a standard factory sample including the following elementary parameters:

| No | Features | Parameters |

| 1 | Application | Factory |

| 2 | Area | 36,000 m2 |

| 3 | Weight | 3,700 tons |

| 4 | Rafter system | Multi-Span |

| 5 | Floor | Mezzanine floor |

Quotation process of Pebsteel pre-engineered building construction

Pebsteel company specializing in the design, fabrication and installation of pre-engineered buildings always desires to provide qualified construction at the most optimal costs of pre-engineered buildings to clients. Pebsteel has the transparent quotation process with suitable solutions for client demands as follow:

Consulting & and providing a preliminary drawing: Pebsteel starts to explore detailed needs of clients in an attempt to begin to design the preliminary drawing and suggest solutions, materials in conjunction with proposed quotation of factory construction.

Contract signing: After clients refer and consent to our suggestion, Pebsteel initiates to complete the contract and essential legal formalities.

After contract signing: Pebsteel begins to develop the detailed technical drawing for fabrication and erection.

Quality designs of pre-engineered steel buildings

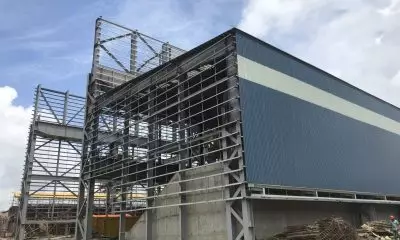

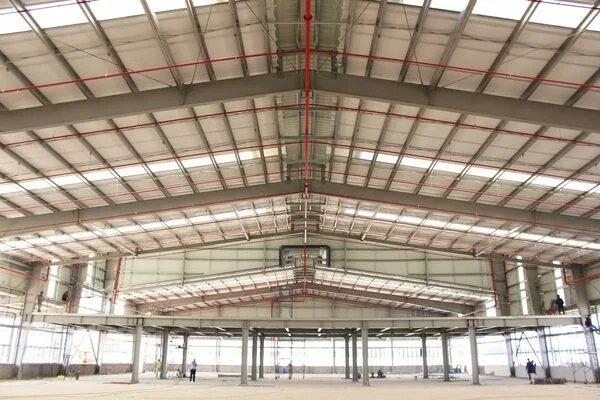

Pebsteel has completed a variety of pre-engineered steel buildings throughout 30 years of experience.

A pre-engineered steel factory with an area of 15,000m2

Design of modern warehouse

Design of an industrial factory

If there is any consulting needs or support about detailed quotation of pre-engineered factory and warehouse construction, don’t hesitate to contact Pebsteel via email pebsteel.indonesia@pebsteel.com for direct consultation.

*** This article is intended to provide general information about the pre-engineered steel building and steel structure industry only. For further details or clarification based on your needs, please contact Pebsteel directly.